A failed membrane is one of the most common causes of water ingress and long-term structural damage in buildings. Whether it’s on a rooftop, balcony, planter box, or basement wall, once your membrane breaks down, water can start to compromise your structure from the inside out.

Knowing how to identify the early warning signs of a failed waterproofing membrane can help prevent widespread damage, expensive repairs, and issues like mould, corrosion, or even concrete cancer. If you’re noticing any of these issues, it may be time to upgrade or repair your system. Learn more about our Membrane Waterproofing solutions and how we help prevent failed membranes from causing long-term structural damage.

What Is a Failed Membrane?

A failed membrane occurs when a waterproofing system can no longer perform its protective role. This often leads to water leaks, damp walls, concrete cancer, and mould. Causes of membrane failure include age, poor installation, UV exposure, structural movement, and physical damage.

Grouped Warning Signs of a Failed Membrane

1. Surface Damage and General Wear

–

Early Signs of a Failed Membrane

These issues are often the earliest signs of membrane degradation and often go unnoticed until more severe damage occurs.

Surface Erosion

Gradual wear of the membrane’s top layer, leading to a rough appearance.

Caused by prolonged UV exposure, weathering, or heavy foot traffic.

Reduces protective capabilities, increasing the risk of water infiltration.

Track Marks

Visible lines or impressions from heavy foot traffic or equipment.

Result from excessive weight or dragging tools across the surface.

May compromise effectiveness.

Scratches

Surface abrasions of varying depth on the membrane.

Caused by contact with sharp objects or debris.

Can expose underlying substrate to moisture, leading to further degradation.

2. Damage from Movement or Environmental Stress

Temperature swings, structural shifts, and pressure can all lead to a failed membrane if the system can’t adapt.

Cracking & Splitting

Fine lines or larger fissures on the membrane surface.

Result of extreme temperature fluctuations or structural movement.

Allows water penetration, leading to leaks and damage.

Buckling

Raised areas or folds in the membrane.

Caused by thermal expansion or trapped moisture.

Increases stress on the membrane, potentially leading to cracks and water intrusion.

Blistering

Raised bubbles on the membrane surface.

Often results from trapped moisture or air during application.

Weakens the membrane’s integrity and can lead to leaks.

3. Installation and Adhesion Failures

Improper application or poor surface preparation is a top contributor to failed membrane systems.

Peeling

Lifting or separation of the membrane from the surface.

Often due to inadequate surface preparation or trapped moisture.

Creates potential entry points for water, jeopardizing waterproofing.

Uneven Surface

Wavy, bulging, or sagging areas on the membrane.

Caused by moisture accumulation or improper installation.

Can lead to water pooling, heightening the risk of leaks.

Bandaid Repairs

Temporary fixes covering leaks or damage without addressing the issue.

Arise from reactive maintenance practices.

Can lead to larger, more expensive problems.

4. Moisture and Contamination Issues

If water has already entered the structure, these issues may appear. They typically confirm the presence of a failed membrane.

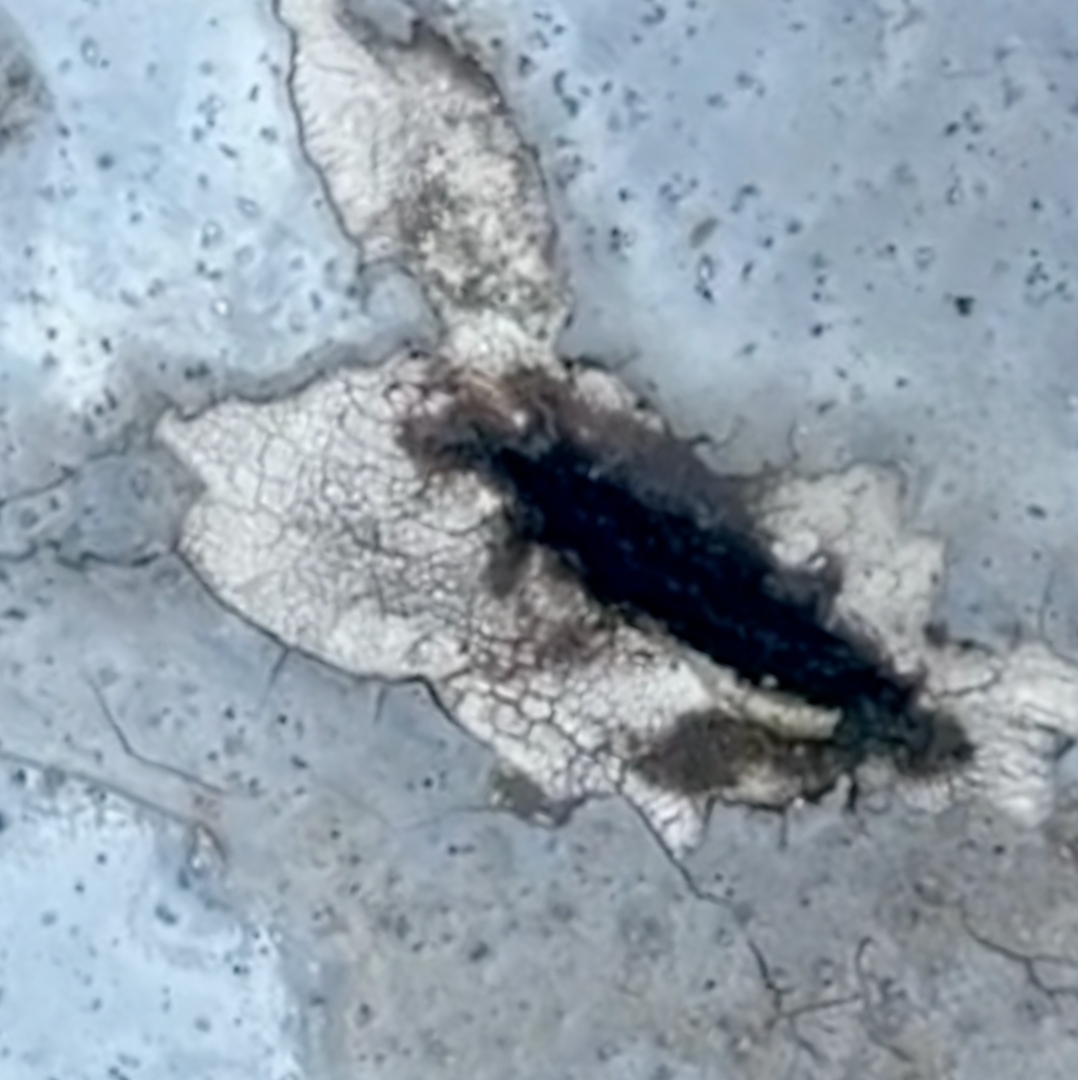

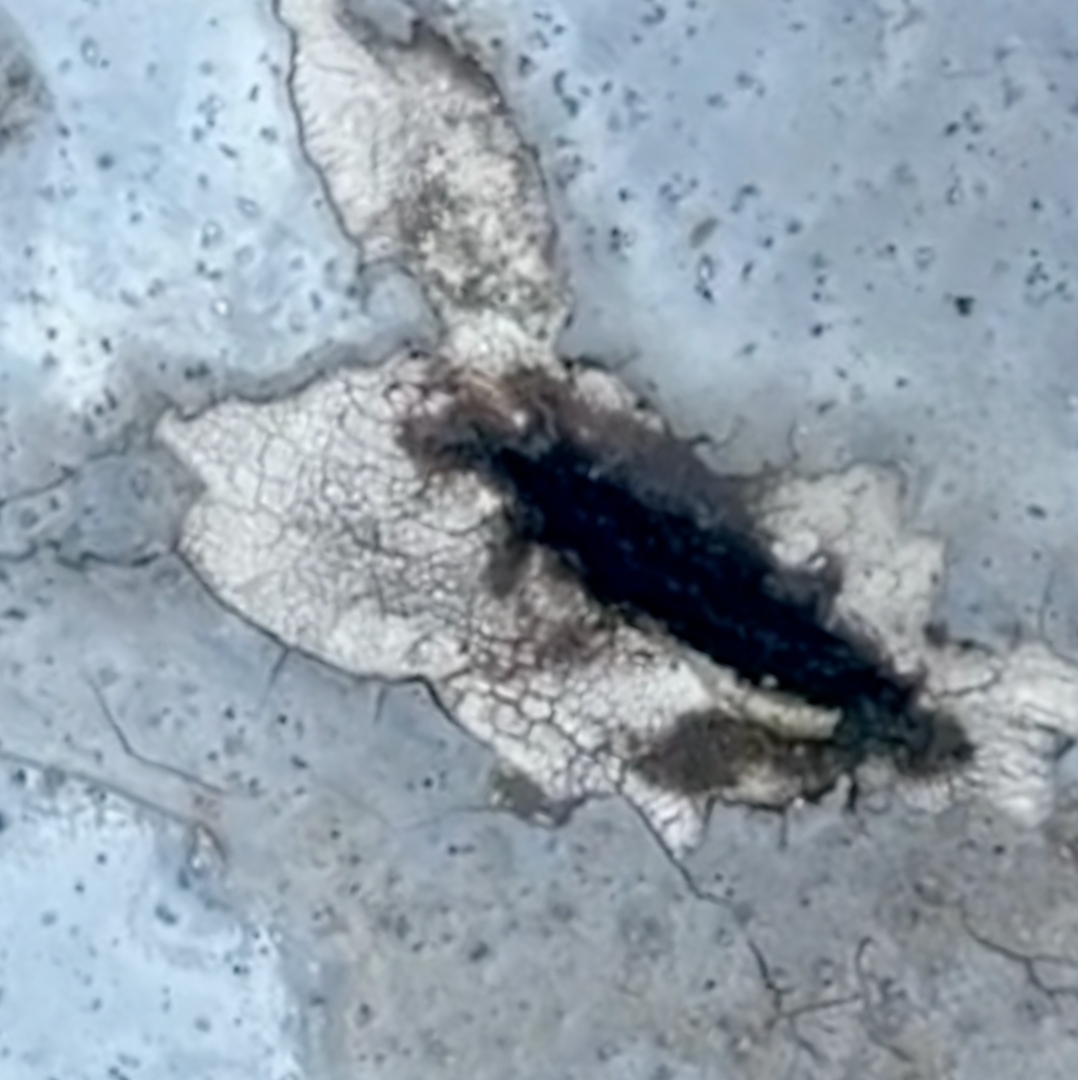

Punctures

Holes or tears in the membrane.

Caused by sharp objects or heavy impacts.

Compromise waterproofing, increasing the risk of leaks.

Mould & Mildew

Dark spots or patches on the membrane.

Caused by excess moisture and inadequate ventilation.

Can pose health risks and degrade the membrane.

Rust Stains

Discolorations from corrosion of metal components.

Result from moisture exposure to rusting materials or inadequate drainage.

4. Moisture and Contamination Issues

Punctures

Holes or tears in the membrane.

Caused by sharp objects or heavy impacts.

Compromise waterproofing, increasing the risk of leaks.

Mould & Mildew

Dark spots or patches on the membrane.

Caused by excess moisture and inadequate ventilation.

Can pose health risks and degrade the membrane.

Rust Stains

Discolorations from corrosion of metal components.

Result from moisture exposure to rusting materials or inadequate drainage.

Concrete Cancer – The Cost of Ignoring a Failed Membrane

When water seeps through a failed membrane and reaches steel reinforcement in concrete, the steel begins to rust and expand. This causes the concrete to crack, flake, and break away—a process known as concrete cancer. It’s one of the most severe outcomes of long-term membrane failure and often requires extensive structural repair.

Why Failed Membranes Need Immediate Attention

Ignoring signs of a failed membrane can result in internal leaks, structural deterioration, health hazards, and compliance issues. The longer it’s left untreated, the more costly the fix.

Need Help with a Failed Membrane?

At Stop & Seal, we specialise in inspecting, diagnosing, and repairing failed waterproofing membranes across commercial and residential buildings. Whether you’re dealing with planter boxes, basements, balconies, or rooftops, our experienced team can help restore your waterproofing system before it’s too late.

Servicing Queensland, New South Wales, and Victoria—including Brisbane, Gold Coast, Sydney Metro, and Melbourne.